Hammer Union fig 1502 Product Features

Hammer Unions are designed to enjoin mud tanks without the need of flanged connections.

The union is made up of three parts, two male ends that weld to the ends of pipe and the threaded nut that forms the connection.

The hammer union is designed to connect mud tanks immediately without having to deal with flange connections at all.

If the storage tank is not aligned in the correct way, the necessary hammer union can still be used to ensure an absolutely leak-free seal.

They usually consist of three parts: male, female and nut.

15000 PSI NSCWP High Pressure Union, Equipped with Lip-Type Seal Ring for Induced Turbulence, Buttweld Connections

Material:

Unions are all steel constructed including precisely manufactured ball-cone (male-to-female) seats.

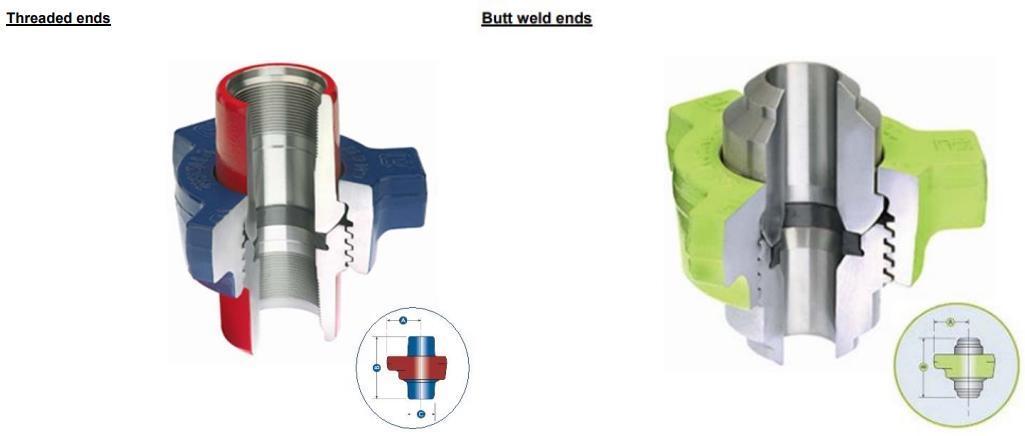

1502 Hammer Union (Blue/Red Sub)

Hammer Unions are designed as heavy duty, high pressure flow line connectors. They are commonly found in chemical plants, on marine dredging vessels, in strip mines and in the oil industry.

The colour coding system on Hammer Unions represent the different configurations and pressure ratings; pressures range from 1,000-15,000 psi depending on the size and configuration.

1502 Hammer Union: Lip type seal ring minimizes fluid turbulence while creating a pressure seal.

For use in mud lines, manifold service and truck mounting applications running air, water, oil, gas or mud up to 15,000 psi non-shock cold working pressure.

1502 Hammer Union:

– Used in cementing, acidizing, choke and kill lines.

– Replaceable lip type rubber seal.

– Available in both threaded and butt weld ends.