About Drilling Mud Pump And parts

What is a drilling mud pump?

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

API 7K Drilling Mud Pump

Where does a drilling mud pump work?

A Drilling Mud Pump is the heart of the mud circulating system.

Generally, the type of triplex single action drilling mud pumps is widely used for oil and gas well drilling.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

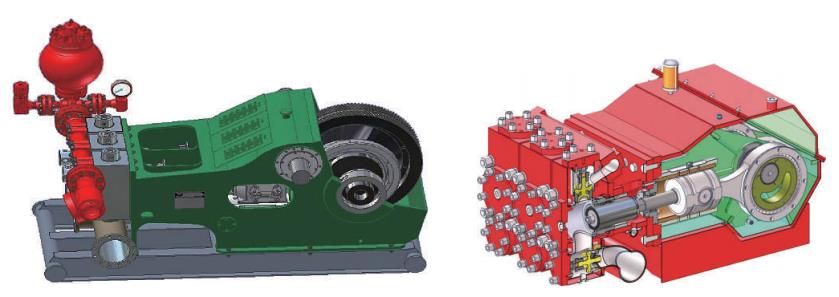

Mud Pump at Well Site

What consist of a drilling mud pump?

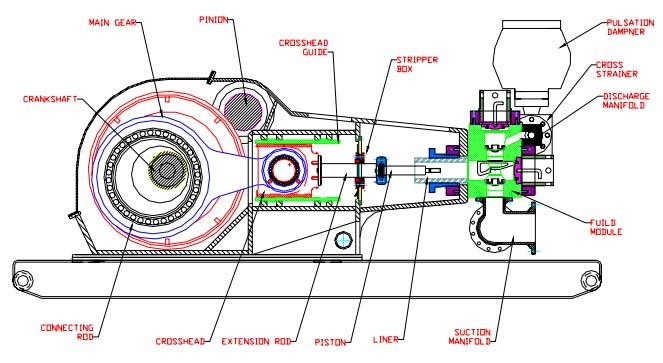

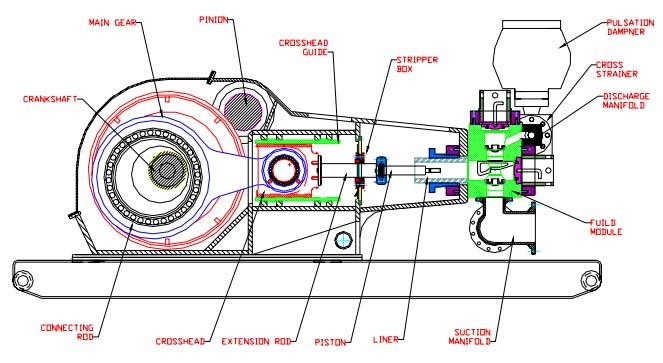

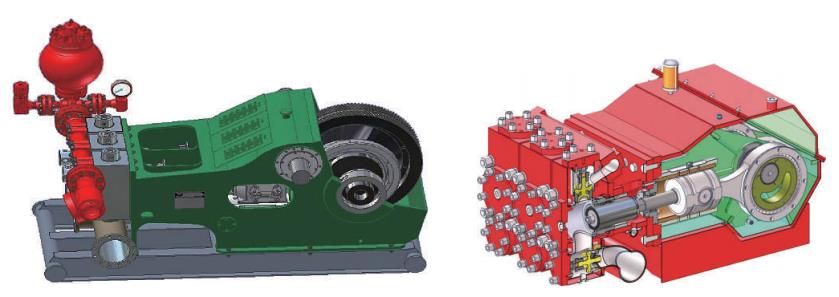

The drilling mud pump is a horizontal triplex single-acting piston pump and consists of two main sections: power end and fluid end.

The power end includes the framework, pinion shaft assembly, crankshaft assembly, crosshead assembly, and crosshead extension rod.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

Click here to view more about mud pumps on our website.

Mud Pump Consists

How does a drilling mud pump work?

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Mud Pump Work

What is the working principle of a drilling mud pump?

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

No alt text provided for this image

How many famous brands drilling mud pumps in the world?

There are many worldwide famous brands for drilling mud pump, including:

Gardner Denver: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11, FK-FXK, FY-FXD, FD-FXX, FG-FXG, PAH-275, etc.

EMSCO: F-350, F-500, F-650, F-800, F-1000, FD-1000, FB-1300, FB-1600, D225, etc.

IDECO: T-500, T-800, T-1000, T-1300, T-1600, etc.

OILWELL: 350-PT, A-650-PT, A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT, HD-1400-PT, HD-1700-PT, etc.

NATIONAL: 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-220, JWS-165-L, JWS-340, JWS-400, etc.

DRILLMEC: 7TS-600, 8T-800, 9T-1000, 10T-1300, 12T-1600, 14T-2200, etc.

BOMCO: F-500, F-800, F-1000, F-1300, F-1600, F-1600HL

LANSHI: 3NB-500C, 3NB-1000C, 3NB-1300C, 3NB-1600

RongSheng: F-500, F-800, F-1000, F-1300, F-1600, etc.

HH: HHF-500, HHF-800, HHF-1000, HHF-1300, HHF-1600, HHF-1600HL, HHF-220HL

etc.

Russia Pump: UNBT-950, UNB-600, 8T-650, UNBT-650, NBT-600, UNB-1180, UNB-1180L, etc.

Weatherford: MP-5, MP-8, MP-10, MP-13, MP-16, etc.

LEWCO / EWCO: WH-440, W600, WH1612, etc.

TSC: WF-400, WF-450, WF-750, WF-1000, WF-1300, WF-1600, WF-200, WF-2200, etc.

TFI: F-500, F-800, F-1000, F-1300, F-1600, etc.

Which interchangeable parts for the above brands mud pump can be supplied?

Mud Pump Parts

For Power End: Pinion shaft, crosshead, pony rod/ extension rod / intermediate rod, bearing, crankshaft, connecting rod, gear, etc.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Please contact JinGao Petro If you are interested in any of these products.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

API 7K Drilling Mud Pump

Where does a drilling mud pump work?

A Drilling Mud Pump is the heart of the mud circulating system.

Generally, the type of triplex single action drilling mud pumps is widely used for oil and gas well drilling.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

Mud Pump at Well Site

What consist of a drilling mud pump?

The drilling mud pump is a horizontal triplex single-acting piston pump and consists of two main sections: power end and fluid end.

The power end includes the framework, pinion shaft assembly, crankshaft assembly, crosshead assembly, and crosshead extension rod.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

Click here to view more about mud pumps on our website.

Mud Pump Consists

How does a drilling mud pump work?

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Mud Pump Work

What is the working principle of a drilling mud pump?

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

No alt text provided for this image

How many famous brands drilling mud pumps in the world?

There are many worldwide famous brands for drilling mud pump, including:

Gardner Denver: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11, FK-FXK, FY-FXD, FD-FXX, FG-FXG, PAH-275, etc.

EMSCO: F-350, F-500, F-650, F-800, F-1000, FD-1000, FB-1300, FB-1600, D225, etc.

IDECO: T-500, T-800, T-1000, T-1300, T-1600, etc.

OILWELL: 350-PT, A-650-PT, A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT, HD-1400-PT, HD-1700-PT, etc.

NATIONAL: 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-220, JWS-165-L, JWS-340, JWS-400, etc.

DRILLMEC: 7TS-600, 8T-800, 9T-1000, 10T-1300, 12T-1600, 14T-2200, etc.

BOMCO: F-500, F-800, F-1000, F-1300, F-1600, F-1600HL

LANSHI: 3NB-500C, 3NB-1000C, 3NB-1300C, 3NB-1600

RongSheng: F-500, F-800, F-1000, F-1300, F-1600, etc.

HH: HHF-500, HHF-800, HHF-1000, HHF-1300, HHF-1600, HHF-1600HL, HHF-220HL

etc.

Russia Pump: UNBT-950, UNB-600, 8T-650, UNBT-650, NBT-600, UNB-1180, UNB-1180L, etc.

Weatherford: MP-5, MP-8, MP-10, MP-13, MP-16, etc.

LEWCO / EWCO: WH-440, W600, WH1612, etc.

TSC: WF-400, WF-450, WF-750, WF-1000, WF-1300, WF-1600, WF-200, WF-2200, etc.

TFI: F-500, F-800, F-1000, F-1300, F-1600, etc.

Which interchangeable parts for the above brands mud pump can be supplied?

Mud Pump Parts

For Power End: Pinion shaft, crosshead, pony rod/ extension rod / intermediate rod, bearing, crankshaft, connecting rod, gear, etc.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Please contact JinGao Petro If you are interested in any of these products.